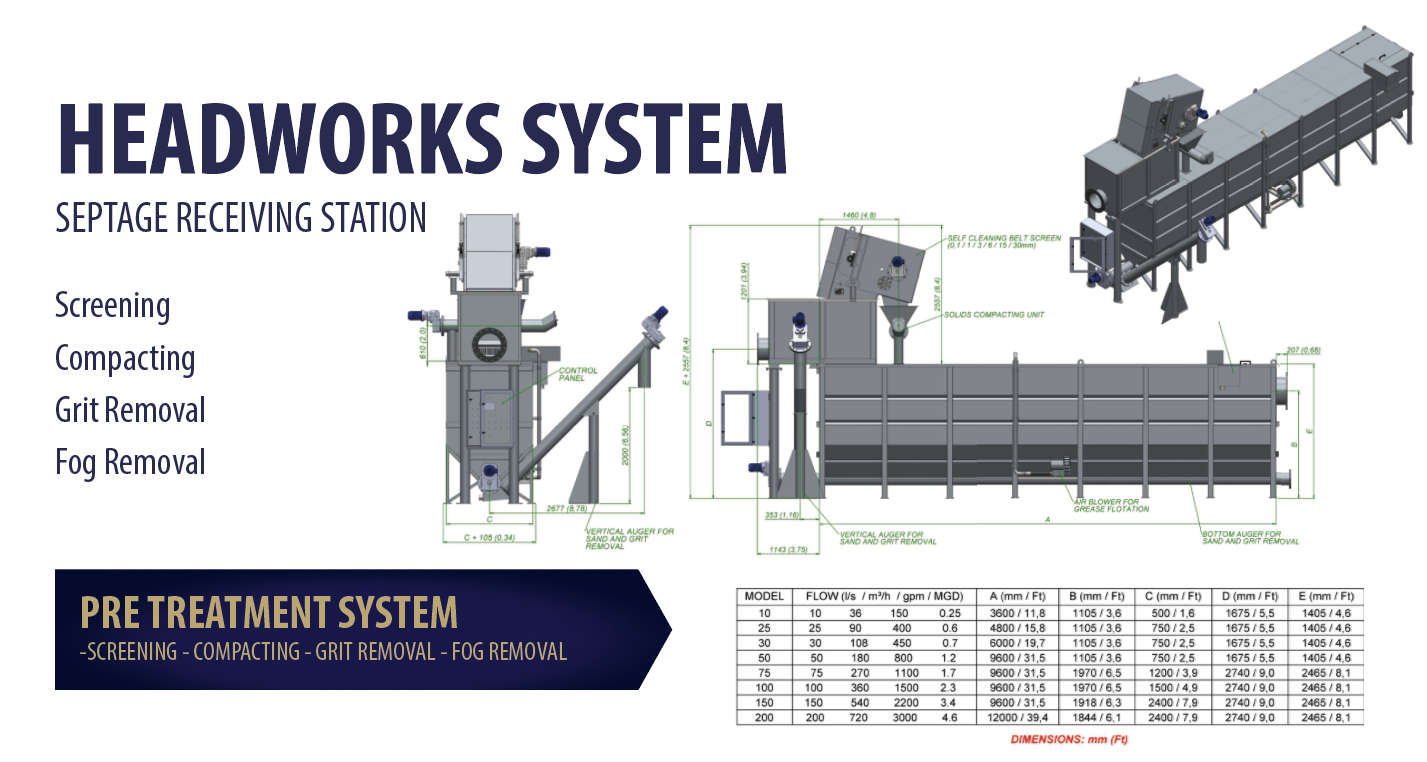

Applications can be based on Municipal or Industrial WWTP. The system uses a belt screen (customer choice 1, 3, 6 or 15mm opening) to remove solids. Wastewater flows through the screen and enters the grit removal chamber while the screened solids enter the compacting unit.

Inside the grit chamber, sand settles on the bottom of the tank and both helicoidal augers (horizontal and inclined) remove the solids out of the tank. Inside the main tank there are stainless steel diffusers connected to an air blower that removes FOG, keeping the sludge blanket on the surface where the automatic skimmer removes it and at the same time the clean water flows through the outlet weirs.

The system has its own complete stainless steel control panel (IP65 for outdoor installation), including PLC-HMI screen where all controls can be set in accordance to the existing flow and solids content. All components, including the augers are 304 stainless steel made with additional UHMW Polyethylene liner for long life operation.

The belt screen used is based on robust de signand minimum maintenance . The self cleaning mechanism keeps the belt clean at every cycle and avoids plugging. Wastewater flow into the unit can be by gravity or pumped. In case of underfloor installation, minimum clearance must be maintained around the unit for operation and maintenance procedures.

PLEASE CONTACT US FOR THE COMPLETE SPECS FOR YOUR APPLICATION

+ 1 801 766 0625

Head Office and Manufacturing Plant

3333 W 1500 N, Lehi UT 84043 – USA

+55 41 3019-3545

Branch office and Manufacturing Plant

Rua Augusto Zibarth 393

85560-360 Curitiba PR – Brasil